Star Packaging Machinery is a Texas based business located in Austin, TX serving Texas, Oklahoma, Louisiana, Arkansas, Missouri, and Kansas.

Star Packaging is a private, family-owned business specializing in Filling, Packaging and Product Inspection equipment sales and support. Our family has been working with clients large and small in the United States on Checkweigher, Metal Detection, X-Ray, Vision, Case Packing, Cartoning, Shrink, and Palletizing projects since 1984.

Our employees have a large amount of experience dealing with manufacturing clients in the food, pharmaceutical, personal care, and contract packaging industries.

We primarily stick to end of line packaging and product inspection, and also sell net-weight filling systems. Take a look at our manufacturing partner list for our most up to date available equipment

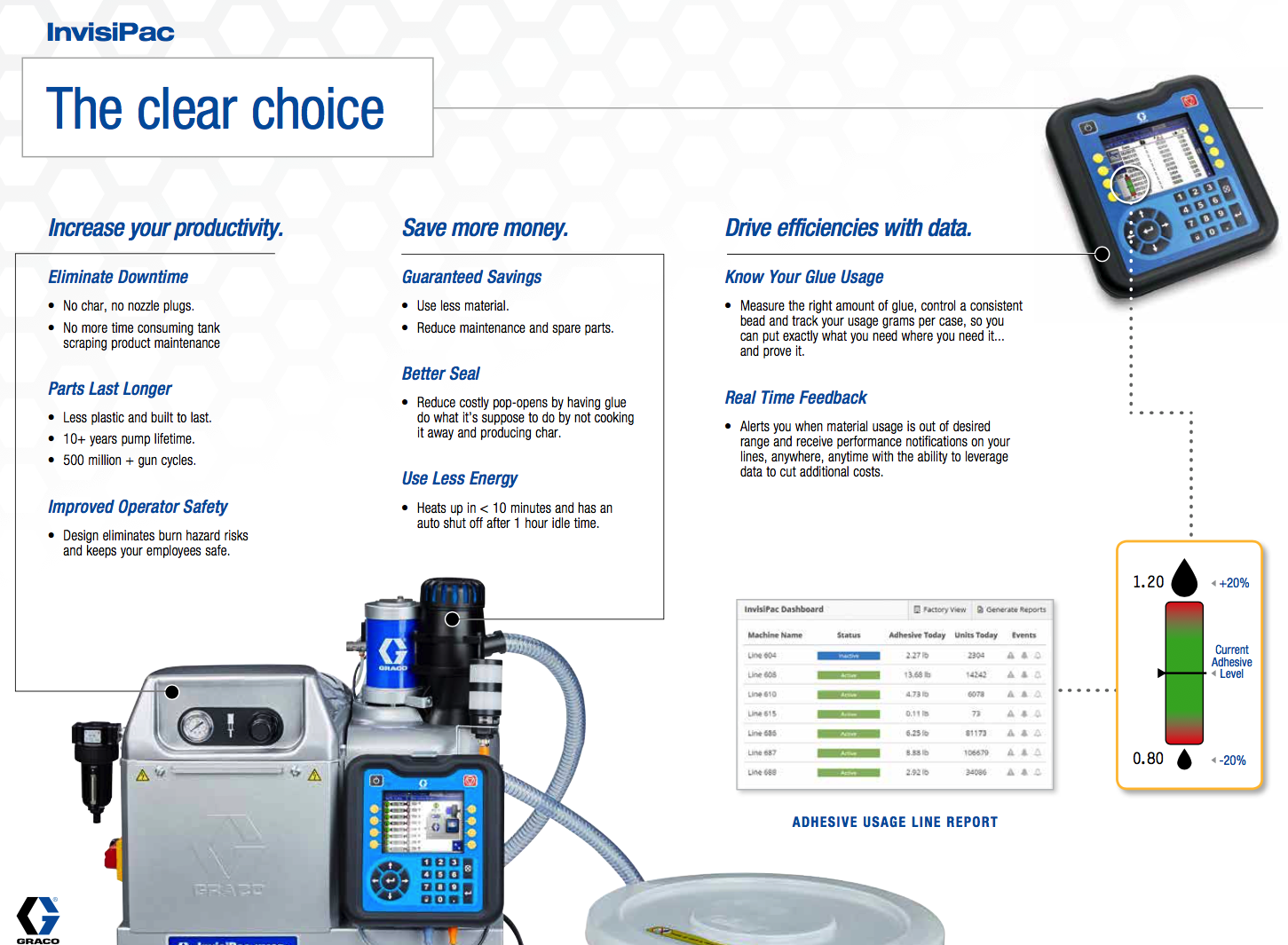

Food, Pharmaceutical, and Industrial Checkweighers – Food, Pharmaceutical and Industrial Metal Detectors – Food, Pharmaceutical and Industrial X-Ray Systems – Food, Pharmaceutical, and Industrial Vision Systems – Automated Cartoners – Automated Case Erectors – Automated Case Sealers – Automated Case Packers – Automated Tray and Shrink Systems – Automated Palletizers – Rotary Labelers – Hot Melt Adhesive Equipment – Liquid and Powder Filling Equipment

Ceia Metal Detection

Italy

In 2009, Ceia brought from their military division to the industrial market a new technology. Being a METAL DETECTOR ONLY company, Ceia is able to invest heavily in R&D and come to market with technologies far before competition. Multi-Spectrum Technology came to the food industry in 2009. Since that time, it has been improved, updated, and perfected to ensure ZERO false rejections when running difficult products. Take a listen.

Ishida X-Ray

Japan

In 2016, Ishida brought to market a new series of X-Ray systems, designed to provide unriveled performance at a lower initial investment. The Genetic Algorithm of the Ishida X-Ray series allows images to be filtered with a high degree of accuracy to provide supeior results. Our clients couldn’t be happier that the user interface has been simplified to provide high level sensitivities on metal, glass, stone, rubber, bone, and other common contaminants.

Columbia Palletizing

Vancouver, WA

In 2019, Star Packaging partnered with Columbia and Columbia Okura to bring a full-range of palletizing solutions for any product and speed to our clients. Columbia has provided over 4,000 clients in the United States with quality palletizing equipment over the past 75 years. Our clients have been very impressed with the Columbia expertise, service, and equipment construction.